Rapid Electroplating Process, Inc. 2901 W. Soffel Ave. Melrose Park, IL 60160-1714 Phone 708-344-2504 Fax 708-344-2514

info@rapidelectroplating.com

Rapid Electroplating Process, Inc.

Manufacturers of Portable Platers for Every Purpose

RAPID Products have been used by government and industry for over 85 years to provide a simple, reliable method of applying or repairing platings.

Pictured is our complete start-up plating kit. Includes power unit, coatalyte, appropriate activator, applicator, abrasive swab, leads, and a jar to rest your anode during the plating process.

One plater can be used to plate different metals. Use one plating unit—you only need to buy the appropriate coatalyte, applicator/anode, and activator. Choose from these metals: Gold, Silver, Nickel, Tin, Cadmium, Zinc, Copper, Brass, Lead, Indium, and RAPIDmetal (a proprietary metal used for XXX).

Why Rapid Electroplating Process Products?

This is True Electroplating

No Special Training Necessary

Use in Shop or Field

Our anodes are made with PURE plating metals, not graphite. When Rapid coatalytes and Rapid anodes are used as directed, you are getting plating from both sources. This results in faster plating.

No non-essentials, order only what you need.

Limited Only By Your Needs and Your Imagination.

Gold Plate PC Contacts to Repair and Prevent Corrosion

Use tin or Rapidmetal to

Prevent Seizing or Galling

Safety Data Sheets (SDS)

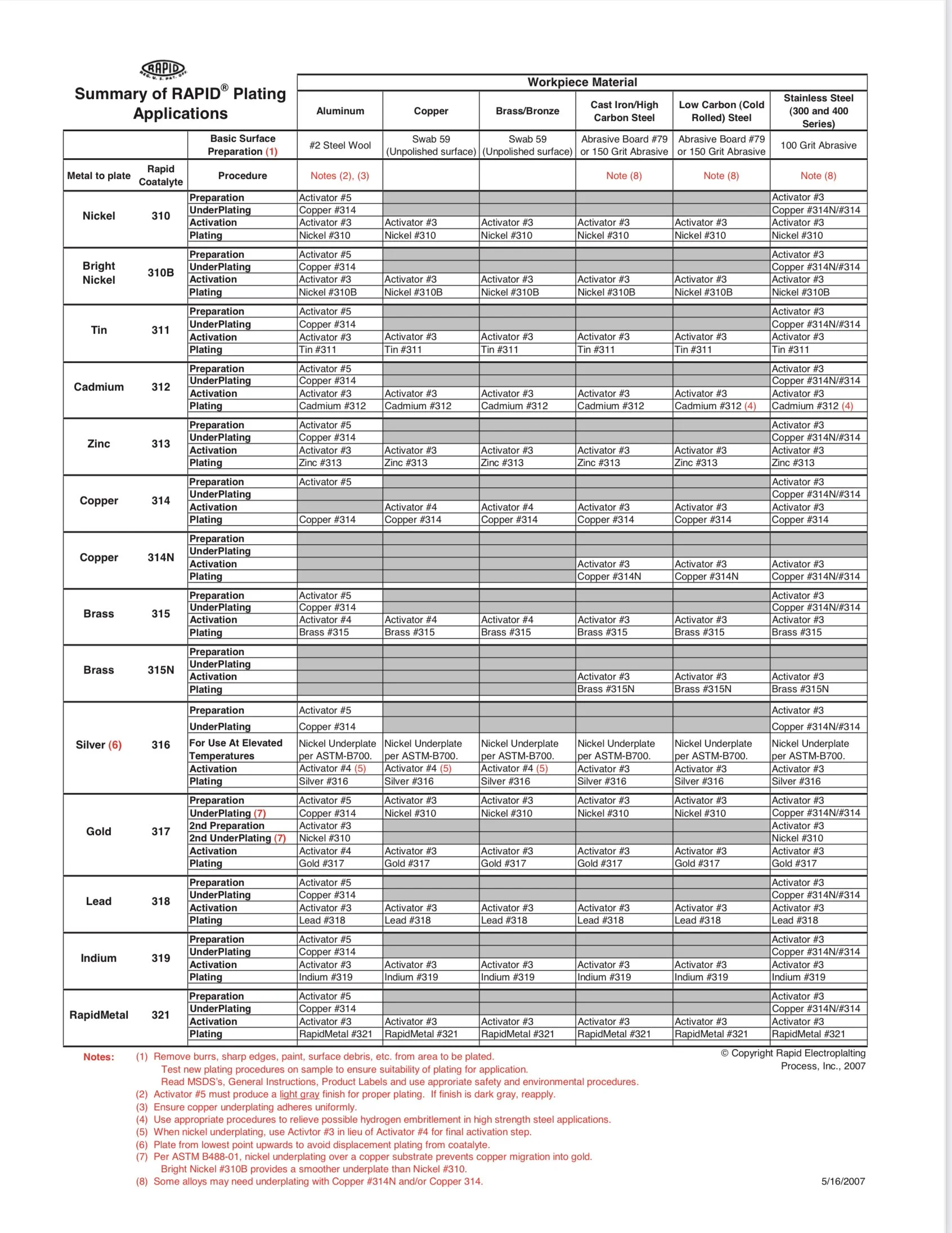

Use this Chart—Just Choose the Metal You Wish to Plate and the

Metal you are Plating Onto to Find the Supplies You Will Need

Supplies to Keep Your Process Going

Coatalytes and Activators.

Pint.

Gallon.

5-Gallon.

Applicators (Anodes with Handle)

3-Inch.

4 1/2-Inch.

5-Inch.

Anodes—Standard or round, square and special shape/purpose anodes are available on request. Contact us with your needs.

Sleeves. Absorbent Cotton and Poly to Carry the Plating Solution.

Miscellaneous

Nickel Plate To Build Up Shafting:

Reduce Production Losses and

Repair Worn Shafting,

Silver Plate Electrical Contacts to Reduce Power Loss

Tin, Cadmium or Zinc Plate to Apply Rust and Corrosion Resistant Coatings

Accessories to Simplify/Expand Your Operation

Plating Fixture. Simplifies Production Runs By Eliminating "Clip Connections" to Odd-Shaped Workpieces.

Test Solution. Tests for Displacement Silver Plating. Verifies Quality Silver Plating.

Power Unit. Augment Your Process for Multiple Operations/Locations.

RAPID Cathode Bar. Simplifies Production Runs By Eliminating "Clip Connections" to Flat Workpieces.

Adapter - Transformer. Converts 220-Volt Systems to 110-Volt for Power Supply.

Supply Case. Carry All Needed Supplies to the Workplace.

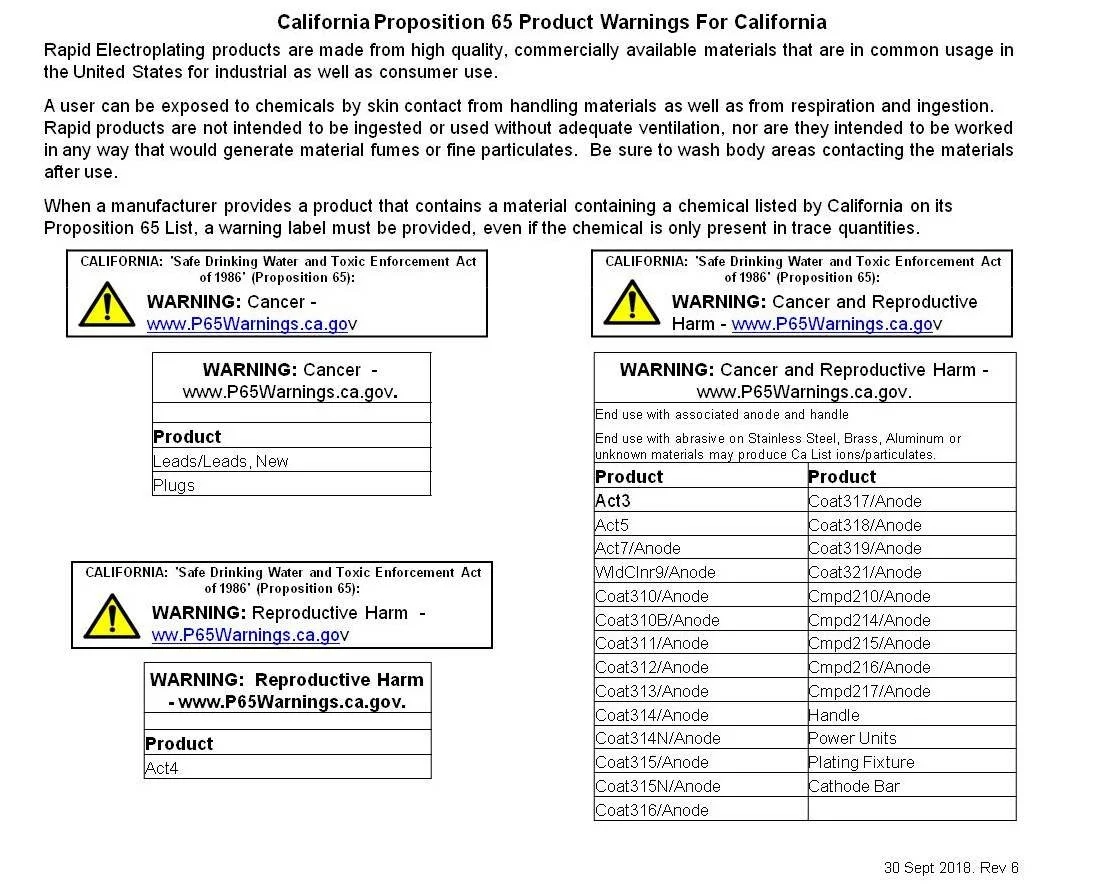

Californiua Proposition 65 Warnings

See www.P65Warnings.ca.gov for more information

Carrying on 85 Years of Quality Hand-Plating

The complete Electroplating Package

Get your complete start-up plating kit. Includes power unit, coatalyte, appropriate activator, applicator, abrasive swab, leads, and a jar to rest your anode during the plating process.

Metals and Anodes

One plater can be used to plate different metals. Use one plating unit—you only need to buy the appropriate coatalyte, applicator/anode, and activator. Choose from these metals: Gold, Silver, Nickel, Tin, Cadmium, Zinc, Copper, Brass, Lead, Indium, and RAPIDmetal (a proprietary metal used for XXX).

Electroplating for Every Purpose

Whether you are plating raw metals or repairing plated components in the field, the Rapid Electroplater will get the job done. And with its dual-source plating technology, it does it faster than graphite anode platers.

Electroplating Supplies

Data-driven audits identify slow-moving stock, recommend reorder points, and streamline warehouse flow to free up working capital.

Let’s Keep In Touch

Ready to improve uptime, cut costs, or simply explore options? Reach out for a complimentary consultation and discover how our team can support your next initiative.

Our Expertise

Built by veterans of manufacturing, supply chain, and mechanical engineering, our team combines decades of floor-level insight with forward-thinking strategies. We translate complex technical requirements into practical solutions that help operations thrive in competitive markets.

Follow Us On Social